Quality and safety:

Not a manual, but a mentality

The terms quality and safety are inextricably linked at RIJKERS. Together they form the foundation of our company and the systems we develop.

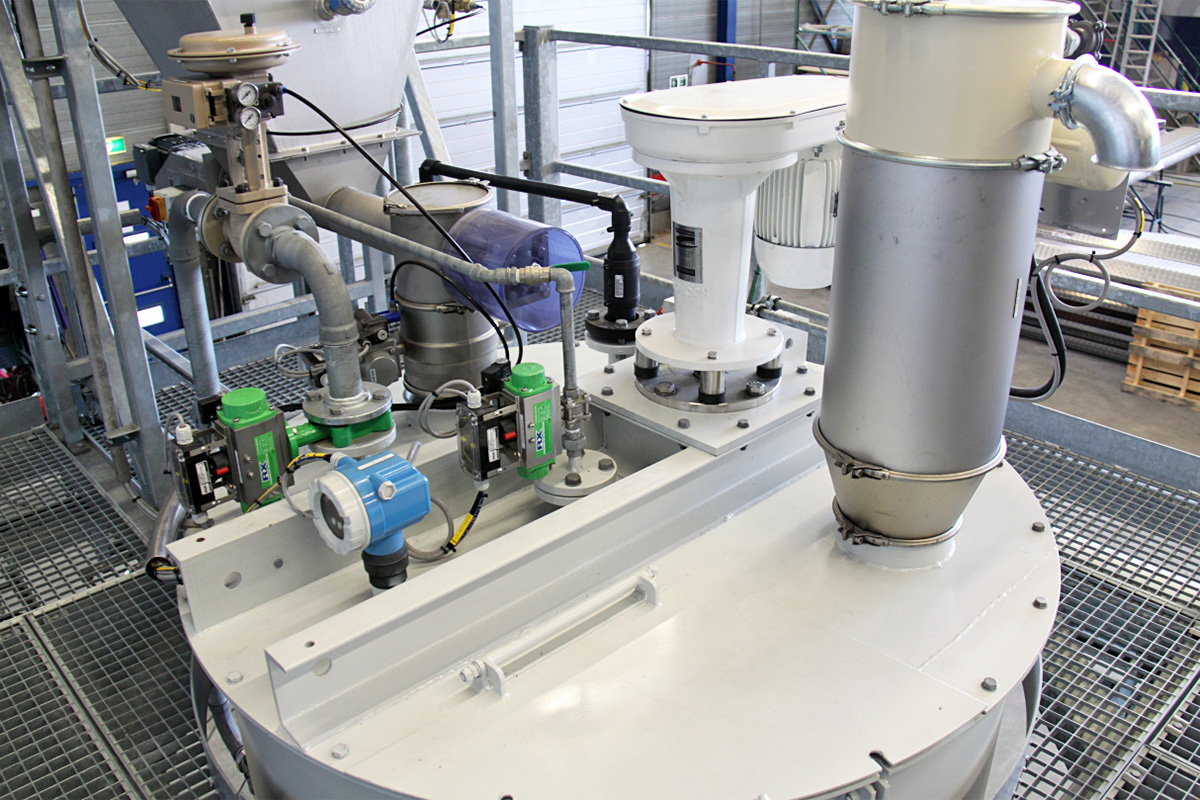

In the food, pharmaceutical and chemical industries, powder or liquid dosing is a critical part of the production process. It involves a delicate interplay between product properties, desired quantities, production conditions and hygiene requirements. This calls for a customized approach in dosing technology.

Do you want to dose powders and dose liquids accurately and correctly? Then you need a dosing system that takes all the above factors into account:

The answers to these questions – and many others – determine the design and construction of your dosing systems. From the dosing method, the piping system, the storage silos and tanks with possible insulation, but also the interaction with the mixing system: everything needs to be geared to your product and the process.

Whether it is liquid dosing or powder dosing: RIJKERS has been specializing in dosing technology for decades. We have extensive experience in dosing powders and liquids, especially in critical industries such as food, pharma and chemicals. We make absolutely no concessions in the area of risk management and focus completely on the reliability and continuity of your processes. When it comes to dosing technology, we only provide customized solutions.

Would you like to know what your system will look like early on, for instance how much space it will take up and what the installation will cost? Then pre-engineering offers the solution.

We are on site, on the shop floor of our customers almost every day to commission, expand and optimize systems, or for service and support. That's why we understand the best practices like no other and know the do's and don'ts. We don't just look at your specific needs during the pre-engineering phase, we also apply our in-house knowledge and experience to achieve the highest level of operational reliability for your equipment. After the pre-engineering phase, we can determine the required budget and give you time to make a well-informed decision.

Dosing is mainly applied in complete process systems with a combination of conveying and mixing, but can also be applied separately and/or as modular process skid.

Dosing according to weight

Dosing according to volume

We produce dosing systems specifically designed for food, pharma and chemicals.

Whether it concerns the dosing system itself or the silos, hoppers, tanks, mixers and piping, we mainly use stainless steel with the very highest degree of finish. Depending on the application, we can also use even higher-grade materials such as titanium, hastelloy, (super) duplex and cunifer, but steel or plastics are also possible.

Request a quoteThe terms quality and safety are inextricably linked at RIJKERS. Together they form the foundation of our company and the systems we develop.