Quality and safety:

Not a manual, but a mentality

The terms quality and safety are inextricably linked at RIJKERS. Together they form the foundation of our company and the systems we develop.

Milk of lime is being used increasingly often for a wider range of applications. This is partly due to the lower raw material costs of lime compared to lye. And that price difference is only growing further. So it's not surprising that more and more producers are opting for a custom-built milk of lime system for producing and dosing milk of lime.

Milk of lime is used for all kinds of applications, such as:

Producing milk of lime and dosing milk of lime demands a carefully considered operational procedure. RIJKERS has years of experience in manufacturing customized milk of lime systems. So it's not surprising that companies choose us as their partner for designing, building and commissioning extremely reliable milk of lime systems that meet the most stringent standards and requirements.

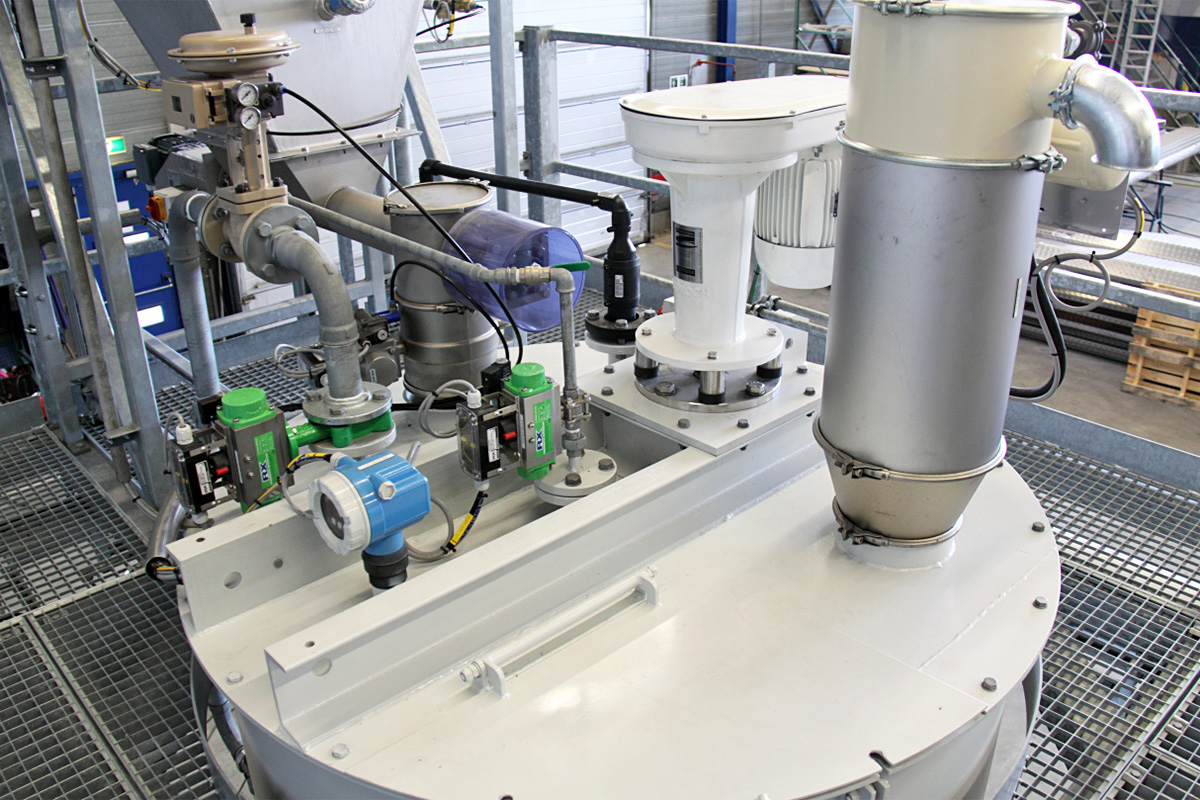

A custom-built milk of lime system usually consists of a mixing system and a dosing system, combined with storage, weighing and conveying. Whether it concerns quicklime or slaked lime, our solutions are based on proven insights, methods and technologies. This means that common problems such as dirt build-up, clogging of pipes and slaking of the milk of lime suspension don't stand a chance.

It is vital that your milk of lime system meets all quality requirements, but it is equally important to make sure it operates without a hitch, every day of the year and with minimal maintenance. We set the bar at 99% operational reliability.

Our only ‘condition’ is that we are allowed to look further than the project scope or the delivery specifications. This generally helps us achieve an even better result: a higher quality of the milk of lime installation, of the production and dosing process and therefore of your product. That's how we keep your business moving forward.

Dredging sediment from the bottom of the waters of the port of Antwerp and storing it is essential to maintain depth and space for shipping. RIJKERS played a role in a successful conditioning process of the sediment with the design and construction of a milk of lime production and dosing system.

Would you like to know what your system will look like early on, for instance how much space it will take up and what the installation will cost? Then pre-engineering offers the solution.

We are on site, on the shop floor of our customers almost every day to commission, expand and optimize systems, or for service and support. That's why we understand the best practices like no other and know the do's and don'ts. We don't just look at your specific needs during the pre-engineering phase, we also apply our in-house knowledge and experience to achieve the highest level of operational reliability for your equipment. After the pre-engineering phase, we can determine the required budget and give you time to make a well-informed decision.

Specific process systems for producing milk of lime and dosing milk of lime.

Several construction options

We manufacture specific milk of lime installations, designed entirely to the required application.

In doing so, we mainly use stainless steel with the highest degree of finish for both the milk of lime system and the silos, hoppers, tanks, mixers and piping system. Depending on the application, we can also use even higher-grade materials such as titanium, hastelloy, (super) duplex and cunifer, but steel or plastics are also possible.

Request a quoteThe terms quality and safety are inextricably linked at RIJKERS. Together they form the foundation of our company and the systems we develop.